Biscuit Manufacturing Business Ideas

The word 'Biscuit' is derived from the Latin words 'Bis' (meaning 'twice') and 'Coctus'

(meaning cooked or baked), history evidence is that biscuits are made since 17th century. Typically, biscuits are small baked products made principally from flour, sugarand fat. They typically have a moisture content of less than 4% andwhen packaged in moistureproof packing materialhas a long shelf life,perhaps six months or more. The appeal to consumers is determinedby the appearance and eating qualities.Biscuits are mainly of two types: hard dough and soft dough biscuits depending on water activity of dough. Biscuits are made in many shapes and sizes with or without embossed designs or logos. They are of different flavours as well they may be coated with chocolate, sandwiched with a fat-based filling.

Biscuit making is a conventional activity in India and in many other countries. The biscuits are produced by organized sector in large quantities, however, unorganized sector having prominent share in market. Despite the advent of modern, large capacity and automatic biscuit making plants, large section of people especially in semi-urban and rural areas still prefer fresh biscuits from local bakery as they are cheap and offer many varieties. These manufacturers are able to cater to some typical local palate as well. Thus, they are able to withstand competition from organized sector units.

PRODUCTS AND ITS APPLICATION

Biscuits products are ready to eat and convenient to use at any place or anytime.

Biscuits having a good food value with substantial energy, protein, carbohydrates and minerals apart from pleasing taste and texture. Handy foods for breaking hunger. Diabetic, protein-rich, gluten-free and multi-grain biscuits are available and capturing good markets among health conscious people.

QUALIFICATION FOR PROMOTER

The promoters must be competent to perform right from market vigilance, product

technology, machinery specs and automation, well versed with food laws, quality

parameters, capable for doing liaison with government and statutory bodies as well for financing for capital and working expenditure.

INDUSTRY OUTLOOK

The biscuit manufacturing industry is growing at the rate of 8% per annum. Now with GST in place more growth will be in organized sector. The trend is to go for more variety, taste,

healthy products and innovative packaging. The completion is also very much in this industry and therefore creativity and innovation in products and packaging will decide the growth of this sub-sector.

Also read:: Agarbatti Making Business

MARKET POTENTIAL AND MARKETING ISSUES

The biscuits and cookies industry in India, valued at INR 15,000 crores is growing at CAGR of 8% over the last three years. It is estimated that the industry will be worth nearly INR 30,000 crores by FY 2019. The industry can be classified into two separate sectors –

organized and unorganized. Biscuits and breads are the major components of the Indian bakery industry and together these two account for almost 80 percent of the aggregate production. Nowadays the biscuit industry contributes approximately 33 percent of the total production of the bakery industry. 70 percent of the biscuits in India are produced by the small scale sector. Per capital consumption of biscuits in India has been estimated at 2 kg. This is fairly low compared to the per capita consumption of over 10kg in the US and the UK and over 4.5kg.in the South-east Asian countries (Hong Kong, Singapore, Thailand, etc.). India is also one

of the leading producers of biscuits in the world along with the US and China. Approximately 17 percent of the biscuits produced in India is exported to locations such as the following:

USA, UK, Ghana, Angola, Haiti, UAE, etc.

With rising incomes, consumers are being lured towards cream biscuits and cookies instead of glucose biscuits Premium biscuits are likely to increase its share by FY 2019 as manufacturers are now aggressively entering the premium biscuit and cookie segment on account of higher margins prevalent in this category.

The leading biscuit brands in India are: PARLE, BRITANIA, PRIYA GOLD, ANMOL, HORLICKS, CREMICA, SUNFEAST, BISKFARM, ROSE, SOBISCO, DUKES, NEZONE, etc. Apart from Indian brands, imported brands popular in India are: OREO, SUMO, HAPPYBITE, etc.

RAW MATERIAL FOR BISCUIT MANUFACTURING

Requirements of Raw Material

1 Maida

2 Sugar

3 Liquid Glucose

4 Palmolein

5 Skimmed Milk Powder

6 Flavour

7 Salt

8 Ammo. Bi-Carbonate

9 Soda

10 Sodium Meta Bi-Sulphite

11 Lecithin

12 Water

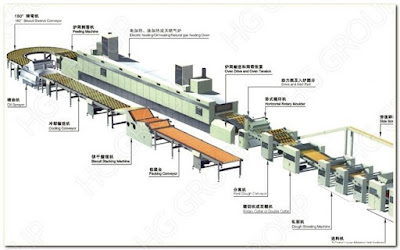

BISCUIT MANUFACTURING PROCESS.

Also Read:: How to start Paper Flower making Business

MANPOWER REQUIREMENT

Manpower Total Requirements Persons

Technical Staff

Adm. Staff

Marketing Staff

Labour

Total 150

BISCUIT MANUFACTURING MACHINE

1 Dough Mixing Machine

2 Hydraulic Dough Crusher

3 Rotary Moulding Machine

4 Swivel Panner Web

5 Turbo Radiant Baking Oven

6 Stripper Unit

7 Cooling Conveyor

8 Magnetic Stacker Unit

9 Packing Table

10 Cream Biscuit Sandwich m/c

11 Planetary Cream Mixer

12 Dough Truck Unloader

13 Horizontal Dough Laminator

14 Rotary Cutting Unit

15 Inclined Feed Conveyor

16 Gauge Roll

17 Intermediate Web

18 Dough Relax Web + Conveyor

19 Rotary Cutting Machine

20 Rotary Cutting Web + conveyor

21 Scrap Conveyor

22 Milk Spray Unit

23 Salt Sprinkler

24 SS Oil Spraying Unit

25 Packaging Machinery

26 Utility & Misc. Equipments

Also Read:: MSME Business Ideas

CRITICAL FACTORS FOR THE PROJECT

1. Biscuit industry is highly competitive and price focused industry besides good

acceptance for taste, appearance, presentation and health oriented declaration.

2. The Indian major players like PARLE, BRITANIA, ITC, PRIYA GOLD, etc. are also

struggling among themselves for capturing market shares in contrast to imported

brands also paving headway in Indian market. So, highly competitive and risk markets.

3. Vigilant selection of plant and machinery, adoption of proper product formulation and technology and hiring of experienced and proven technical manpower are key factors to penetrate the competitive markets.

4. Purchase and selection of right quality of all inputs at right price is a major critical factor to bring plant in profitability.

5. Avoid wastage, deploy required manpower, regular maintenance of plant and

machinery, devise product runs for production to minimize gas consumption and

cleaning processes are also equally critical factors to run plant efficiently.

GOVERNMENT APPROVALS

There is statutory requirement of FSSAI license for setting up of food processing industry. Moreover, MSME& GST registration, IEC Code for Export of end products and local authority clearance may be required for Shops and Establishment, for Fire and Safety requirement and registration for ESI, PF and Labour laws may be required if applicable. Entrepreneur may contact State Pollution Control Board where ever it is applicable.

BACKWARD AND FORWARD INTEGRATION

Forward linkages can be established by introducing ready to eat snack foods and also bread

making to cater the same distribution channel. Also after well establishment of the trade name,

promoter may think of giving franchise to other entrepreneurs in the country.

TRAINING CENTERS/COURSES

For food processing industry training and short term courses are available at Indian Institute of Food Processing Technology, Thanjavur, Tamil Nadu and Central Food Technological Institute, Mysore. 'Udyamimitra portal ( link : www.udyamimitra.in ) can also be accessed for handholding services viz. application filling / project report preparation, EDP, financial Training, Skill Development, mentoring etc.'

Thanks for this post...Any Biscuit Machine Manufacturer would begin the assembling of bread rolls with the center item i.e spread and sugar. Be that as it may, the roll world isn't restricted to mixture fixings, consistency, baking principles and so on; it's an alternate world actually.

ReplyDeletePotato chips line supplier

Pasta line supplier

chocolate moulding machines

Project management consultants

Post a Comment